การฉีดขึ้นรูปแรงดันต่ำ(LPM) VS การฉีดขึ้นรูปแบบดั้งเดิม

2022-07-28

กระบวนการบรรจุภัณฑ์แบบเดิมมักใช้การฉีดแรงดันสูง เมื่อเทียบกับกระบวนการฉีดแรงดันต่ำแล้วนั้น การฉีดแรงดันสูงมีจะมีแรงดันฉีดและอุณหภูมิที่สูงทำให้ส่วนประกอบที่มีความเปราะบางเกิดความเสียหายได้ง่ายในระหว่างกระบวนการฉีดและทำให้เกิดความบกพร่องในการผลิตง่าย

| การฉีดขึ้นรูปแบบเดิม | การฉีดขึ้นรูปแรงดันต่ำ |

| ● แรงดันฉีดสูง (350-1300Bar) | ● แรงดันฉีดต่ำ (1.5-40Bar) |

| ● อุณหภูมิการฉีดสูง (230-300 ℃) | ● อุณหภูมิการฉีดต่ำ (180-230 ℃) |

| ● แม่พิมพ์ทำจากเหล็กเท่านั้นทำให้แม่พิมพ์เกิดการสึกหรอสูง | ● แม่พิมพ์สามารถทำจากหลากหลายวัสดุ ไม่ทำให้แม่พิมพ์เกิดความเสียหาย |

| ● ไม่สามารถฉีดชิ้นส่วนอิเล็กทรอนิกส์ที่มีความแม่นยำได้ | ● มีกระบวนการบรรจุภัณฑ์ที่เหมาะสำหรับส่วนประกอบที่มีความละเอียดอ่อนและแม่นยำ |

| ● โดยทั่วไปแล้วสารพลาสติกทางวิศวกรรมจะมีความหนืดต่ำเมื่อเทียบกับวัสดุประเภทต่างๆ | ● วัสดุและผลิตภัณฑ์ในการฉีดมีการยึดเกาะที่ดีและประสิทธิภาพการกันน้ำและการปิดผนึกสูง |

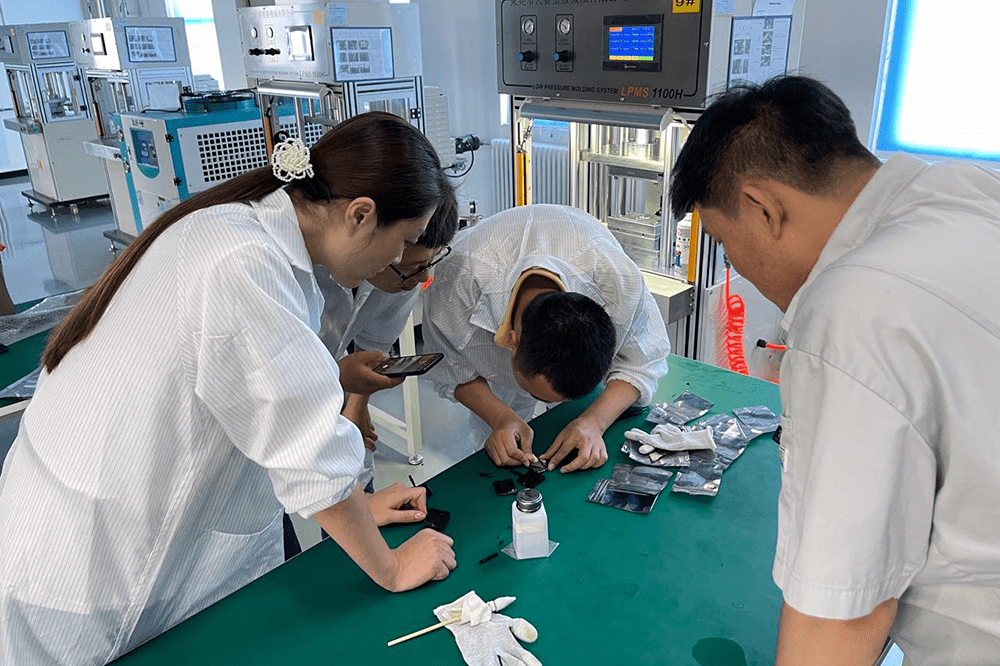

วิศวกรของเราได้เลือกชุดผลิตภัณฑ์กาวร้อนละลายฉีดแรงดันต่ำที่มีความหนืดต่ำและมีความลื่นไหลสูงหลังจากการหลอมเหลว โพลีเอไมด์ฉีดแรงดันต่ำต้องใช้แรงดันเพียงเล็กน้อยหลังจากการหลอมละลายจึงจะไม่สร้างความเสียหายให้กับส่วนประกอบที่เปราะบางซึ่งจำเป็นต้องบรรจุและลดอัตราความเสียหายได้อย่างมาก

ในส่วนของอุณหภูมิการฉีดนั้น อุณหภูมิการฉีดของกระบวนการฉีดขึ้นรูปแรงดันต่ำยังต่ำกว่าอุณหภูมิการฉีดแรงดันสูงแบบเดิม ซึ่งช่วยลดโอกาสที่จะสร้างความเสียหายให้กับส่วนประกอบที่มีความละเอียดอ่อนและแม่นยำเนื่องจากอุณหภูมิที่สูงเกินไป

ในแง่ของต้นทุน เนื่องจากแรงดันในการฉีดต่ำและการเสียดสีบนแม่พิมพ์มีขนาดเล็กมาก แม่พิมพ์ขึ้นรูปแรงดันต่ำจึงสามารถทำจากแม่พิมพ์อะลูมิเนียมหล่อแทนเหล็ก ซึ่งง่ายต่อการแปรรูปและสามารถย่นระยะเวลาในการพัฒนาได้อย่างมาก

ในแง่ของฟังก์ชันการทำงาน กาวร้อนละลายฉีดแรงดันต่ำให้คุณสมบัติการปิดผนึกที่ดีเยี่ยม เมื่อเปรียบเทียบกับพลาสติกวิศวกรรมทั่วไปที่ยากต่อการรวมเข้าด้วยกันและไม่มีฟังก์ชันกันน้ำ กาวร้อนละลายแบบฉีดแรงดันต่ำสามารถยึดเกาะกับวัสดุหลากหลายชนิดได้ดี ด้วยการออกแบบผลิตภัณฑ์ที่เหมาะสมจึงทำให้สามารถตอบสนองข้อกำหนดการกันน้ำระดับ IP67 หรือสูงกว่าได้อย่างง่ายดาย

จากคุณสมบัติข้างต้น เทคโนโลยีการฉีดขึ้นรูปแรงดันต่ำช่วยลดข้อบกพร่องของการฉีดขึ้นรูปแรงดันสูงแบบดั้งเดิมและกลายเป็นทางออกที่ดีที่สุดสำหรับส่วนประกอบอิเล็กทรอนิกส์และไฟฟ้าขนาดเล็ก ไม่เพียงแต่ให้การปกป้องทางกลและสารเคมีเท่านั้น แต่ยังให้การปกป้องในระยะยาว มีความน่าเชื่อถือในขณะที่ลดต้นทุนและปรับปรุงประสิทธิภาพเช่นกัน

สิ่งเหล่านี้ทำให้การฉีดแรงดันต่ำมีความได้เปรียบทางการแข่งขันที่สำคัญในกระบวนการบรรจุภัณฑ์และนำความเป็นไปได้ใหม่ๆ มาสู่วงการอุตสาหกรรม