We provide customized expandable braided sleeving for you, whether it is material, size or color.

2022-05-19The application of Expandable Braided Sleeving

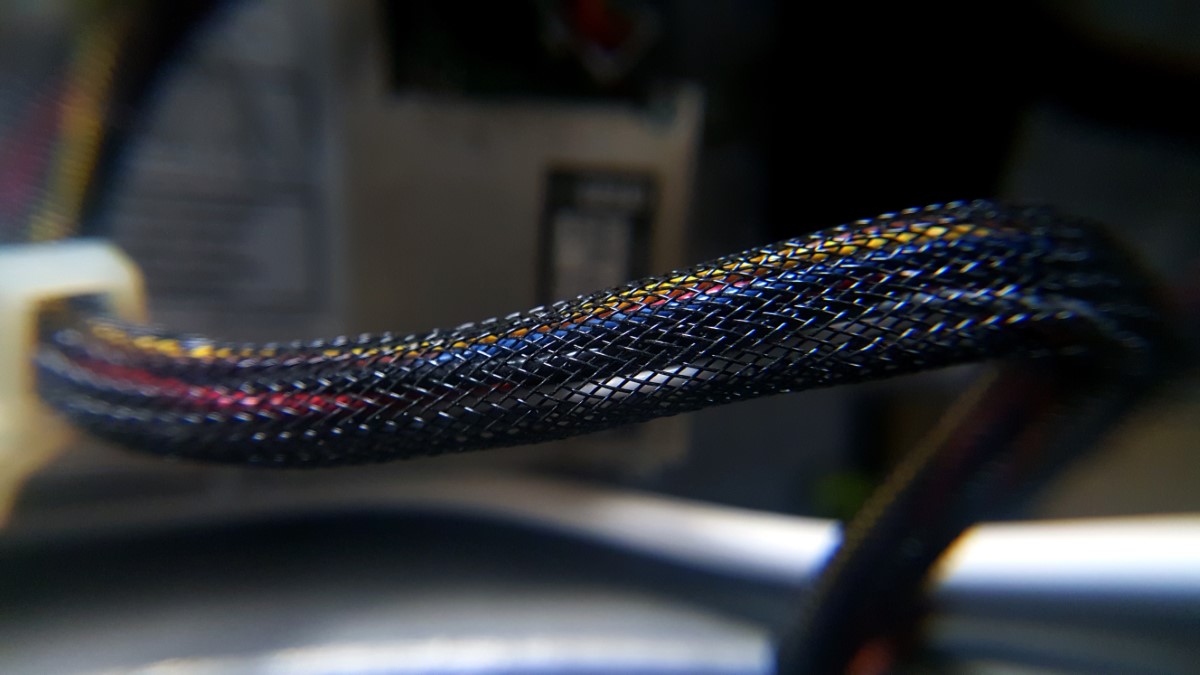

The expandable braided sleeving is made of PET monofilament or Nylon monofilament, which is widely used in protecting and bundling multiple cables such as computer power cords, household appliances, outdoor cables, automobiles, etc. It has the advantages of good flexibility, flame retardancy, and wear resistance, is easy to use, is flexible, and wide application range.

The material of the Expandable Braided Sleeving

PET (Polyethylene Terephthalate)

PET can meet the requirements of wear protection in various fields. Its unique braided structure has good expandability, which can be expanded to 2 times the original diameter. It has very good expandability for bulky connectors that need to pass through. It is easy to operate, and it will not generate static electricity due to friction when applied to frequently-acting automation equipment. It is UV resistant and VW-1 flame retardant.

Nylon

The expandable braided sleeving is woven from nylon 66 monofilament, which has better wear resistance, chemical resistance, softness, and other characteristics. It has excellent toughness at low temperatures and is more suitable for automotive and irregular shapes, but the cost is higher than PET.

Tinned shielded braided sleeving

The braided sleeving is woven from nylon yarn after tin plating. This product has the characteristics of EMI electromagnetic signal shielding, lightweight, and good flexibility. They are widely used in servers, Netcom equipment, aviation, and other fields.

Self-wrappable braided sleeving

It is woven from PET monofilament and multifilament polyester fiber, and the split-wrappable design is convenient for installation and unloading when both ends are closed. The extremely soft material provides anti-wear protection and good shock absorption and sound absorption, which can replace corrugated Tubing, to avoid the noise caused by plastic friction, widely used in automotive occasions, especially suitable for wire harnesses with irregular shapes.

How to use the Expandable Braided Sleeving: When cutting, you need to use a hot knife to cut the incision to prevent the incision from spreading. Choose an expandable braided sleeving with a suitable expansion range according to the outer diameter of the workpiece. The folding diameter refers to the flat width of the sleeving.

Braiding is not only an art but also our core technology

Before the boom of the electronics industry, Good Gi Co., Ltd had been studying braided sleeving. Owning more than 1,500 braiding machines, which can weave expandable braided sleeving of different materials, widths, colors, and patterns with monofilament or trifilament according to customer requirements.

For the quality control of the expandable braided sleeving, as long as it is the characteristic parameters listed in the specification, our company can detect and control it continuously. There are also low-temperature bending testers that can test whether the expandable braided sleeving will break under the extreme cold of -50°C, as well as various oil and solvent resistance testers, and even to detect whether the expandable braided sleeving is environmentally friendly, RoHS or vertical and horizontal flame resistance in our laboratory.