ケーブル固定ヘッドとは?ケーブル固定ヘッドの選び方は?

2022-04-29|

目次: |

ケーブルグランドを知る

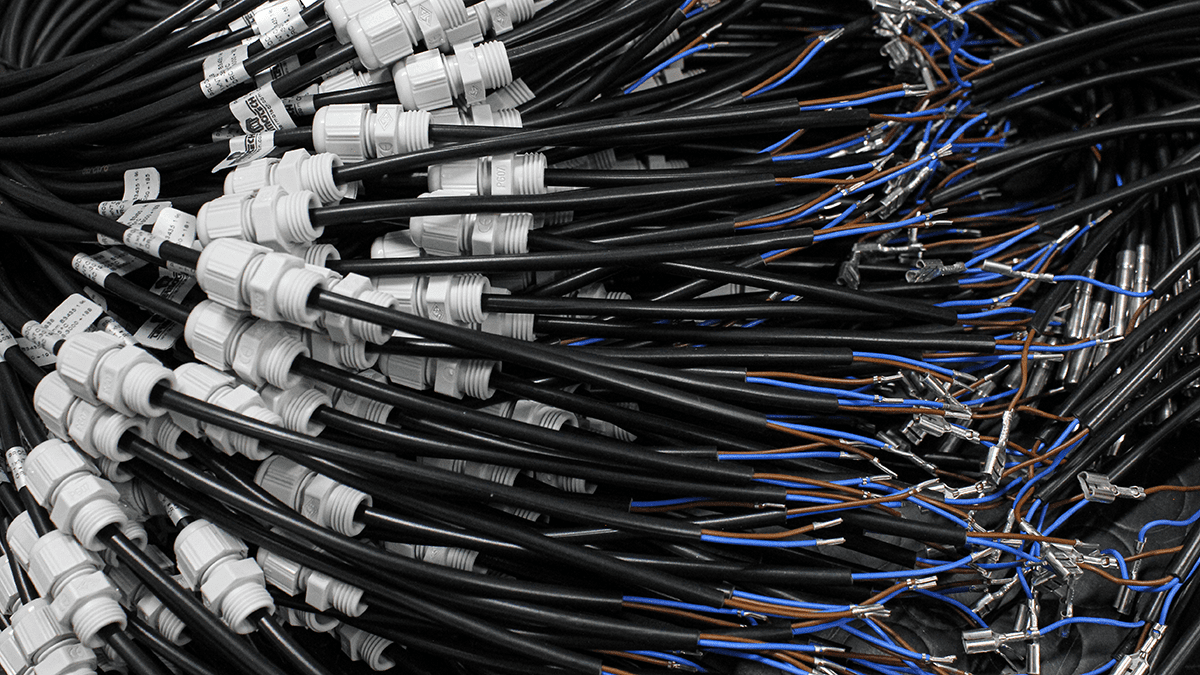

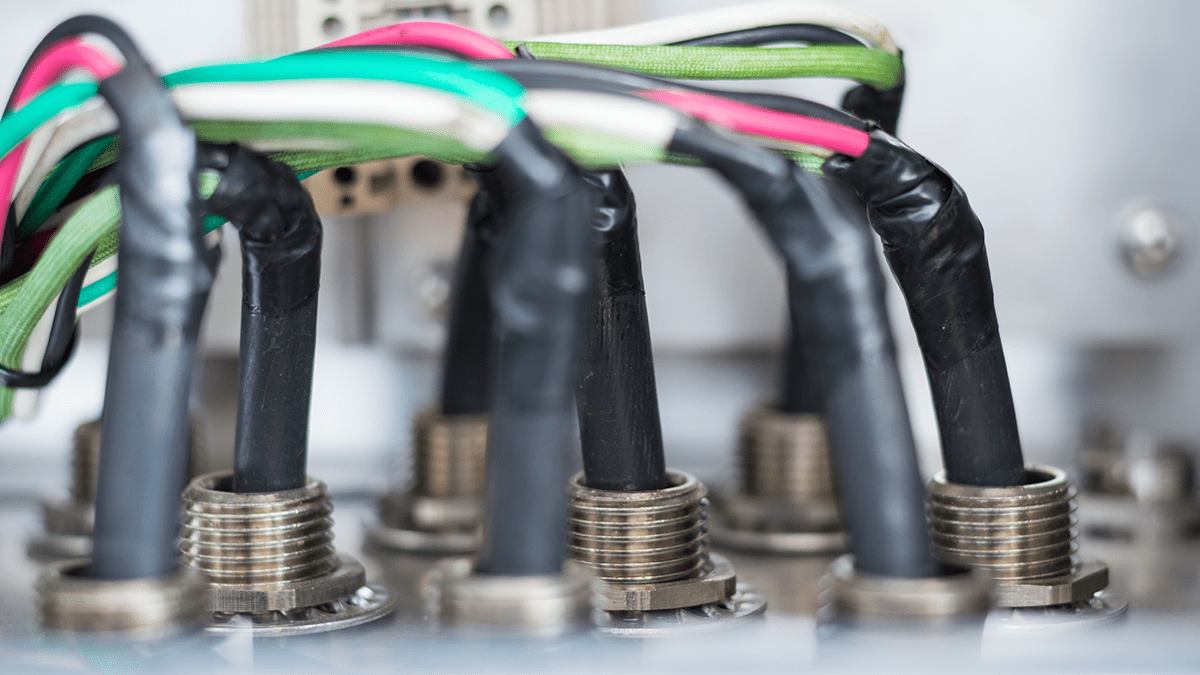

ケーブルグランド(Cable Gland)は、精密機械設備、各種配電盤、制御ボックス、船舶の電気設備、屋外機器の電線・ケーブルの固定および保護に広く使用されています。主な役割は、ケーブルの貫通穴を密閉し、防水・防塵を確保することです。これにより、危険なガスが計器や接続ボックスに入り、ショートや爆発を引き起こすのを防ぎます。また、水分の侵入は絶縁性能を低下させ、電子機器の寿命を短くする可能性があります。

なぜケーブルグランドを使用するのか?

ほとんどの機械や設備は、機器を運転させるために電源を供給するため、または信号を伝送して設備がその指示に従って動作するために、電線やケーブルを使用して接続されます。そのため、外部の電線が機器内部に接続される際には、設備の外側のパネルに穴を開け、電線やケーブルが内部に通るようにします。パネルに穴を開けて電線を通した後、電線を固定し、保護する必要があるため、ケーブルグランドが登場します。

ケーブルグランドの種類?

-

直型ケーブルグランド:標準型

-

L型ケーブルグランド:90度の角度で出線

-

耐ねじり型ケーブルグランド:線材の折れ曲がり防止

ケーブルグランドの一般的な材質

-

ナイロンケーブルグランド(Nylon)

一般的な環境に適用。

-

亜鉛合金ケーブルグランド(Zinc Alloy)

高い機械的強度が求められる製品や、長期間屋外で使用される製品に適しています。

-

真鍮ケーブルグランド(Brass)

IP68防塵防水等級、耐塩、弱酸、アルコール、油脂、一般的な溶剤に強い。プラスチック素材よりも堅牢で、耐腐食性と耐荷重性に優れています。再生可能エネルギー、産業オートメーション、電気設備に広く使用されています。

-

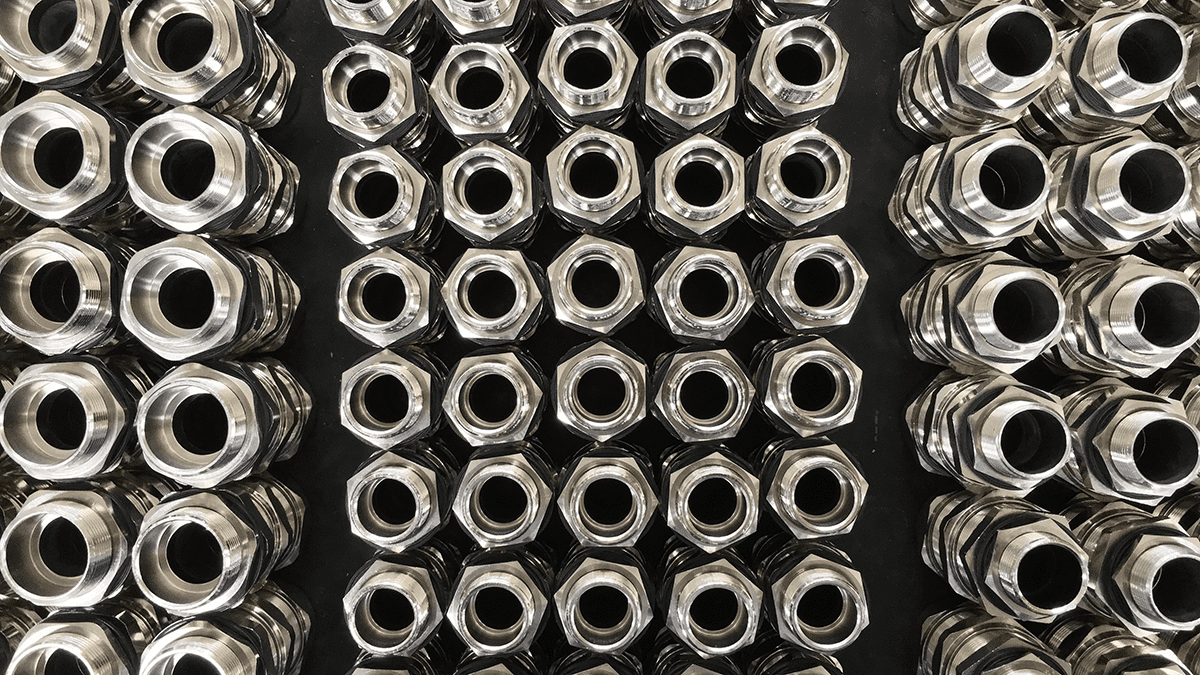

ステンレス鋼ケーブルグランド(Stainless Steel)

より高い耐腐食性を持ち、機械的強度が要求される過酷な環境に使用されます。

-

特殊素材ケーブルグランド(Special material)

耐油、耐寒、難燃、耐高温など、特別な要件がある環境で使用されます。

適切なケーブルグランドの選び方?

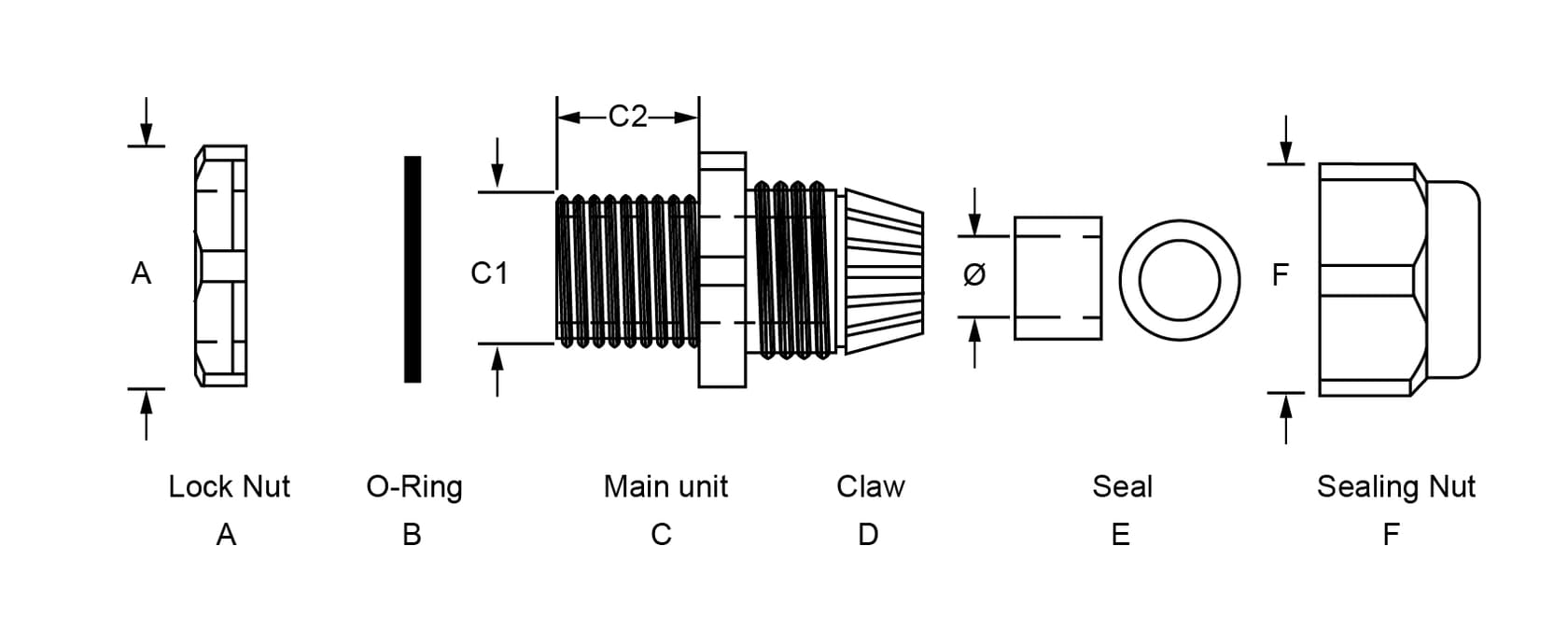

まず、使用環境に応じて材質を決定します。たとえば、耐温性が適合するかどうかを確認します。ナイロン素材(上図A C F)は-40℃〜100℃まで対応可能です。クランプリングおよびパッキン(上図B E)がEPDMの場合、-60℃〜160℃まで対応可能です。また、防水・防塵等級がIP68に達していることを確認し、難燃等級は原料によりUL94HB、UL94V-2、UL94V-1、UL94V-0(最高)に分かれます。さらに、耐酸・アルカリ、耐油機能が必要かどうかも確認します。

現場の設備の出線方向に応じてケーブルグランドの種類を決定します。谷騏は、直型、90度角度型、耐ねじり型を提供しており、誤った使用や過度なストレスで電線が危険になるのを防ぎます。

最後に、サイズ規格を確認します。まず、ゴムインサートの内径がケーブルの外径に合っていることを確認し、ケーブルとケーブルグランドが完全に密着し、十分な引張強度を持つことを確認します。次に、接続部のネジの長さが機器のパネルを貫通し、ナットを固定できるかを確認します。谷騏は薄いパネル用に短いネジも提供しており、厚いパネルには長いネジも適しています。もしタップされた穴がある場合、ねじの種類(Mねじ、PGねじ、Gねじ、NPTねじなど)を確認します。最後に、接続部の外径が設備の構造に干渉しないことを確認します。