7 must-knows about Expandable Braided Sleeve

2022-11-10

|

After reading this article, you will know more about Expandable Braided Sleeve: |

The use of Expandable Braided Sleeve

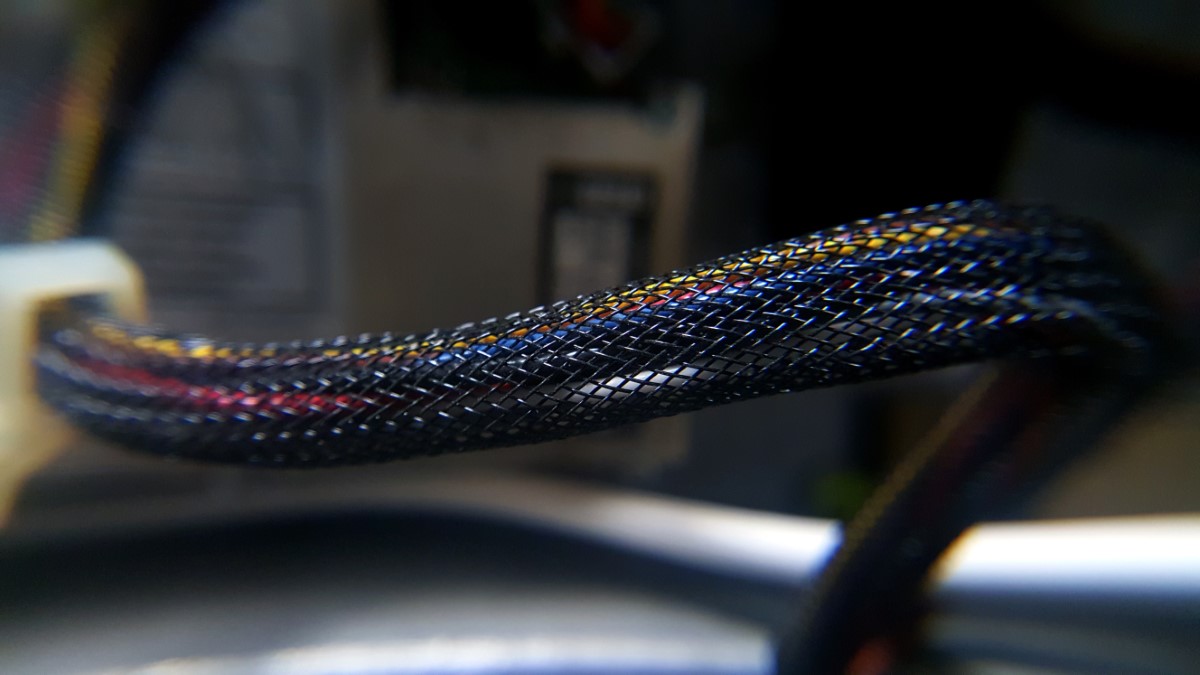

The Expandable Braided Sleeve is used to protect the cable, and at the same time, it solves the problem of poor covering due to irregular shape, and is easy to install. With good elasticity, stretchable, wear-resistant, corrosion-resistant, usually made of polyester (PET) monofilament or nylon (Nylon) monofilament braided, widely used in computer power cords, household appliances, outdoor cables, Cars etc.

Features and Advantages of Expandable Braided Sleeve

-

Flexible and bendable

It is suitable for equipment with complex wiring, and can be flexible to install in a small space.

-

Neat cable management

It can neatly collect and classify complex and huge wire groups, optimize equipment wiring, save identification speed, and improve the professional image of products and companies.

-

Good expansion elasticity to covering object with irregular shapes

It can expand to capable of covering multiple wire bundles or large cables. Good expansion and elasticity, even irregular shapes can fit the shape.

-

Protection

Depending on the material, it can provide protection such as wear resistance, heat resistance, flame retardant or breathable shielding, effectively improving the durability of wires and cables.

What are the materials of Expandable Braided Sleeve?

-

Polyethylene Terephthalate(PET)

Polyethylene terephthalate (Also called PET or PETE). PET can meet the requirements of wear protection in various fields. Its unique braided structure has good expandability, which can be expanded to 2 times the original diameter. It has very good expandability for bulky connectors that need to pass through. It is easy to operate, and it will not generate static electricity due to friction when applied to automatic equipment. It is UV resistantand VW-1 flame retardant. 。

-

Nylon

Nylon expandable braided sleeve is woven from nylon 66 monofilament, which has better wear resistance, chemical resistance, softness and other characteristics. It has excellent toughness at low temperature and is more suitable for automotive and irregular shapes, but the cost is higher than PET.

-

Tinned

The braided sleeve is woven from nylon yarn after tin plating. This product has the characteristics of EMI electromagnetic signal shielding, light weight and good flexibility. Widely used in servers, network equipment, aviation and other fields.

What are the styles of the expandable braided sleeve?

-

Braiding

Repeat the overlapping process to create a flat or three-dimensional technique, the middle is not tight or even empty.

-

Textile

The process of weaving vertically up and down creates a flat surface with a relatively tight middle, which is stable and not easily deformed. Usually, the appearance is a self-wrappable design to cover the wires.

Applications of Expandable braided sleeve

-

Computer room

Contains computer classrooms, laboratories, data centers, etc., with spaces for transformers, generators, and a large amount of electrical wiring. There are often needs for shielding, wear resistance, heat resistance and flame resistance. While protecting the wires, the appearance can be optimized together. Quickly identifying the position of the wires can also help the company save time and improve efficiency.。

-

Car

Braided sleeves are also a common accessory used to protect cables and wires when the interior of the car is relatively tight and the engine is subject to vibration and high temperature. It is flexible, wear-resistant and heat-resistant.

-

Ship

With the use of braided sleeve, the cabin wires can be secured and are often used on engines, control panels, etc.

-

Industrial manufacturing

In the face of harsh environments, extreme high temperature, humidity changes, impact and vibration, the braided sleeve can fully resist.

-

Automated machines

Including expensive products such as robots and robotic arms, sensitive and precise motion design, braided sleeves can provide excellent cable protection.

How to choose the suitable size of the expandable braided sleeve?

-

Measure the diameter of object

-

Choose according to the degree of fit required

If you want a tight fit, you can choose the diameter of the braided sleeve slightly smaller than the diameter of the cable; if you want a loose and flexible fit, please choose the size of the braided sleeve with a diameter larger than the diameter of the cable.

*Expand of the braided sleeve will result in a shorter length, please consider and calculate the extra length when using it.

How to fix Expandable Braided Sleeve?

Don't know how to fix the cable after passing it through the expandable braided sleeve? Basically, you can choose the following three ways to deal with it:

-

Tape

It is a most economical and convenient tool and just need to wrap the tape to the junction.

-

Cable Ties

It is also an economical and cheap tool, which is faster than adhesive tape, and there are many colors for marking.

-

Heat Shrink Tube

It is a little time-consuming, but it is often used in the aviation and automotive industries, because it has better protection effect and can withstand heat and wind. Simply slide the tube over the end and heat to shrink with a heat gun or blow torch.

Where and how to buy Expandable braided sleeve?

Why choose to buy from Good Gi?

Braiding is an art and our core technology.

-

Over 30 years of manufacturing experience.

- Experienced manufacturing technology can adjust the production layout more flexibly and quickly.

- Rich industry experience, providing one-stop services, providing more complete solutions and professional assistance.

- Perfect management mode, high-efficiency and high-quality completion of punctual and fast delivery targets.

-

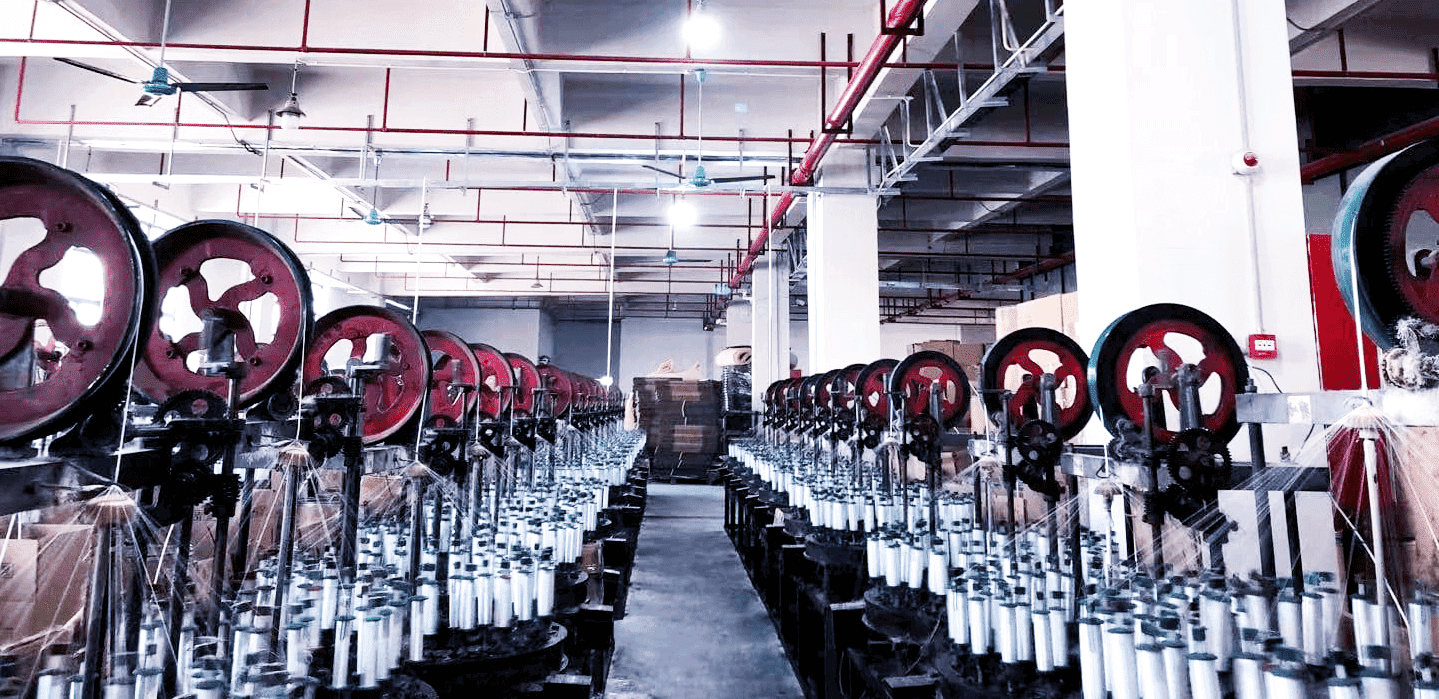

More than 1500 braiding machines

Before the boom of the electronics industry, Good Gi had already begun to study braiding tubes. We have more than 1500 braiding machines, which can braid sleeves of different materials, widths, colors, and textures with monofilament or three-filament according to customer requirements.

-

Strictly control the quality – In-house testing in our own laboratory

For the quality control of the expandable braided sleeve, as long as the characteristic parameters listed in the specification, our company can detect and have continuous control. We have Aging Oven Tester that can perform long-term high-temperature aging tests and melting point tests on the extendable braided sleeve. There are also low-temperature bending testers that can test whether the expandable braided sleeving will break under the extreme cold of -50°C, as well as various oil and solvent resistance testers, and even to detect whether the expandable braided sleeving is environmentally friendly, RoHS or vertical and horizontal flame resistance in our laboratory.

-

Quality Assurance

- Made in Taiwan.

- Passed multiple third-party international certifications such as ISO and you can trust us when purchasing products from Good Gi.

- Strict control and calibration of real-time tests in our own laboratory.

-

Regular stock

Good Gi prepares stock to meet the temporary needs of users and sample needs.

-

Cost advantage

It’s more efficient and saves costs if customers can purchase products from manufacturer to get products faster and more affordable.